|

|

|

|

Main Description

Single Coil Parts Kit

We've been offering these single coil parts kits for a good long while at this point, so its probably long over due that we go into a little more detail in the write up, so, here goes.

This is a full kit to make one single coil pickup, containing everything you'll need except the coil wire - on the face of it, a fairly simple thing, however, there are so many variables, and so many options, it probably makes sense to detail everything here.

This Kit includes

1 x Fiber Board Single Coil set (Base and top, either Black or Grey, to suit pole diameter)

6 x Alnico pole pieces (In the selected Diameter, Grade and Length)

2 x 6/32 UNC Mounting bolts (In selected colour)

2 x Nickel plated brass Eyelets (no fitted to fiber board)

1 x 52mm Cover (to suit pole diameter)

2 x Height adjustment springs OR silion tubes

Optional extras

1 x Focusing plate (more information under the Focusing plate section)

2 x Focusing plate mounting screws

1 x Meter of black cloth covered wire

1 x Meter of Yellow OR white cloth covered wire

Please note, this kit is not supplied assembled or magnetised unless otherwise selected under the "constructions option" section.

Fender®, Squier®, Stratocaster® and Strat® are registered trademarks of Fender Musical Instruments Corporation and Axesrus® has no affiliation with FMIC

Does Pole staggering matter?

This ones one those things that crops up every so often, and i dont think anyone really has a straight answer, so i figured i'd try and explain what pole staggering is, and whilst i probably cant say "this is better then that!", atleast your slightly better informed.

Why does it exist?

So, traditionally? a single coil pickup comes with staggered poles - specifically, the E and A poles (17.5mm long poles) are shorter then the D ang G poles (18mm) , the B pole (16.5mm) is shorter again, and the high E (17mm) is slightly higher. Its very common, and is an idea thats been around since the very first Stratocaster, and exists purely to "balance" the strings, because the wound strings are "quieter" then the unwound (because they constain less steel within those nickel wraps essentially) and with the 7 1/4" radius necks of the 50s, the strings sat further away from the pickup compared to more modern, flatter radius' necks.(old guitars had worse actions, basically)

Interestingly, on the very first Strat single coil models, the staggering was different, with a 17.5mm being used on the G string, which caused the wound Gs of the time to be slightly too quiet, and that was phased out in 1956 for the "normal" staggering we see pretty much everywhere nowadays.

However - that change in 56, is interesting - because, really, it was done to account for wound G strings... which are a bit of a rarity nowadays (with "unwound Gs" becoming common in the 70s), so why has the idea of staggering not evolved further?

Now, this is going to get a little more into the psychology of guitars rather then the science of pickups, and i dont have all the answers on this front, but if we take this information with a pinch of salt, it does make some sense - and it all boils down to the unavoidable truth of guitar parts in general.

"Pickups with staggered poles have been used, from 1954 until (on the whole) this morning, to make all the music we listen to"

And knowing that?

We're basically at a weird point where we've got to admit "all we've ever heard" is music played on the Stratocaster, with pickups that had staggered poles. Its the sound we like. Nowadays, its actually a slight imbalance in the strings, but its something we've grown to love.

Sure, the staggering might have been designed for wound Gs, which we no longer use, sure, necks are, on the whole, flatter then they were in 1957, and allow us to get a much lower action, and the idea of a staggered pole doesn't make a great deal of sense any more, because we're not fighting the same problems we'd have faced the fifties.... but, that doesn't change the fact that our favourite new band, formed in 2019, who play guitars from that year, are all STILL playing pickups with staggered poles. Its just standard practise now, so, dont fight the tide - staggering is the norm, so stick with it, it might be wrong, but its sounds right!

The Exception

Flat necks!

Whilst i can sit here and say "staggering is wrong, but its the wrong we know" - it is still, on the whole, quite helpful! With either a 7 1/4" or a 9 1/2" radius neck being the standard on most models, the only thing thats "wrong", usually, is the G string - theres still enough of a curve in the neck to get the strings sitting far enough away from the pickups face to warrent having staggered poles.

But - when we get away from that? When we get into the world of 12" and 14" and Compound radius necks? We actually come out the other side of the problem. We're not capable of getting the strings so "flat" across the face of the pickup, that staggering is actually causing more of an inbalance in string volume then correcting it.

so, if your playing a guitar with a flatter radius neck - avoid staggering! (its also not a bad idea if your making a HSS or HSH setup either, because no one adjusts the poles on their humbuckers in the same way) - Non-staggered poles will give you more consistent results.

In summary

Warts and all replicas? vintage re-issues? Meet your hero guitars? Where your working with 7 1/4" radius necks? Those of us stubborn enough to still be buying wound Gs? Go for staggering!

Modern guitars based on old designs? 9 1/2" radius? 7 1/4" radius but not using wound Gs? Normal guitars? Your still wanting staggering!

Ultra flat necks? HSH and HSS setups? Super low action? Your probably going to want non-staggered.

Magnets Explained

Coming Soon in full

In Brief - Magnet grade (and diameter) are tied together to some extent, but, ignoring the fact that "bigger magnets are stronger" for the time being, essentially, the weaker the magnet you use on a pickup, the less voltage the pickup produces at its resonant peak.

This means that a pickup would with weaker rod magnets, will sound smoother, less spiky, and less aggressive when compared, like for like, with the same pickup constructed on stronger magnets.

Whilst its very tempting to get sucked into the colourful language of pickups, and see words such as "smooth" and "rounded" as positives (and i'll certainly concede, there are times and places when those characteristics are desirable!) - remember, the Stratocaster tone we know, ALWAYS uses alnico 5s, so always exibits that prominant, aggressive, high resonant peak frequency and narrow Q.

We can move away from that with weaker magnets, but remember, you are fundementally changing the DNA of the pickup at that point, so results may not be what your expecting.

Focusing Plates

Coming Soon in full

In Brief - Focus plates are metal base plates that mount to the bottom of a pickup, and change the way the magnets are behaving.

All 3 options will attenuate to pickups voltage at the resonant peak, making the pickup feel smoother and more rounded, and theres some minor variation with there that resonant actually sits depending on material.

Brass pushes the

resonant peak higher, but retains a little more of the pickups Q factor, giving it a slightly more defined smoothness, with a tighter mid range.

German Silver/Nickel retains almost everything about the pickup, EXCEPT the voltage at the peak - so this is the most transparent "smoothening" - this will make the pickup feel more round, without losing anything in the low and mid range.

Steel pushes the resonant peak into a lower frequency, but retains everything else about the pickup, resulting in the pickup feeling slightly darker, and more aggressive, as well as being more rounded.

Construction Options

Right then – to get straight down to the nitty gritty of this

We WILL, at request, assemble (and magnetise) your single coil kits – this includes pressing the poles into the fibre boards, setting the internal height to the specific dimension (and charging the poles to their maximum gauss) and installing the eyelets – however, this is done at extra cost, and, because it’s a fairly labour intensive job, that cost isn’t exactly cheap.

So, in for the sake of complete transparency – if your in the market for a single coil kit, assembled and magnetised, so the only thing you have to do, is put the wire on there? Please, think long and hard on it!

Just running the quick sums, I can spec up a single coil kit, ready for wire and termination, for just over £30 – or I can sell you a completed (very high spec) single coil, for just over £60!

I appreciate that the idea of making a single coil may be very tempting, but if your going to do it, your really better off investing in the tools, and perfecting the process from start to finish – paying one of our techs to do the assembly, is going to quickly make it “uneconomical”

Obviously, if your just starting out, I get that it may be tempting to skip the whole “assembly” step yourself, but I can’t stress this enough, you are infinitely better off learning to assemble and magnetise your own pickups then having us do it. You’ll be better placed in the future should anything weird come across your desk, and you will be a better winder as a result.

So, whilst its an option, and I certainly wont begrudge anyone from taking it, if your in this for the long term? Please, do it yourself.

How to Assemble

Using fibre boards to make pickups is an ideal that started about 80 years ago, and it was done simply because its a very cheap way of making a pickup. It was, however, never intended to be something you'd DIY, so its not exactly a user friendly process. Even before you start winding, theres a process to actually putting the "frames" together.

Youre going to need the following "tools" (Ideally...)

1. An Arbour Press - nothing too extravigant, but an arbour press isn't THAT expensive, but it'll make your life so much easier.

2. A Spacer - Something to set the height of the pickups "internal" - usually, a single coil is 11.3mm internal height, but its not exactly a critical dimension. No ones going to scream and shout if your new single coil is 11mm or 12mm, but you'll definately need "something" to stop the top fibre board compressing down too far. Most people use a couple of chunks of wood, but specialist jigs do exist, and if your doing this more then a few times, you'll want to either buy one, or make one!

And thats about it in terms of tools, but you'll obviously need your parts.

Its as expected really.

6 Pole Pieces (Usually some grade of Alnico Magnet - they'll need charging up too, but thats one for another article)

a Fibre board set (A base and a top)

A pair of eyelets to connect the coil wires to.

So, lets get stuck into it.

Pole Spec

Pole Height - 1 x 16.5mm (B) 1 x 17mm (High E), 2 x 17.5mm (A, and Low E) and 2 x 18mm (D and G).

Pole Width - 5m, 3/16" or 1/4"

Material - Light Beveled Alnico (non-magnetised)

Please note - all measurements are accurate to within 0.2mm

Fibre Board Spec

Botton Pole Spacing - 52mm

Top Pole Spacing - 52mm

Cover Spec

Height - 13.5mm

String Spacing - 52mm

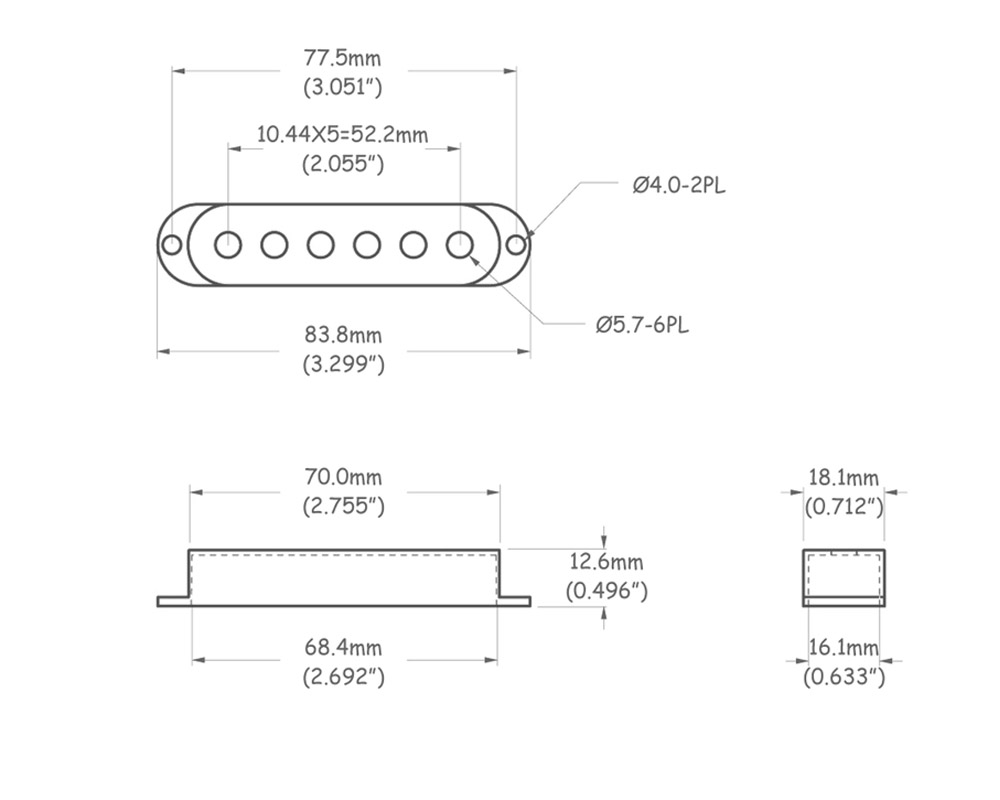

5mm and 3/16" kit spec

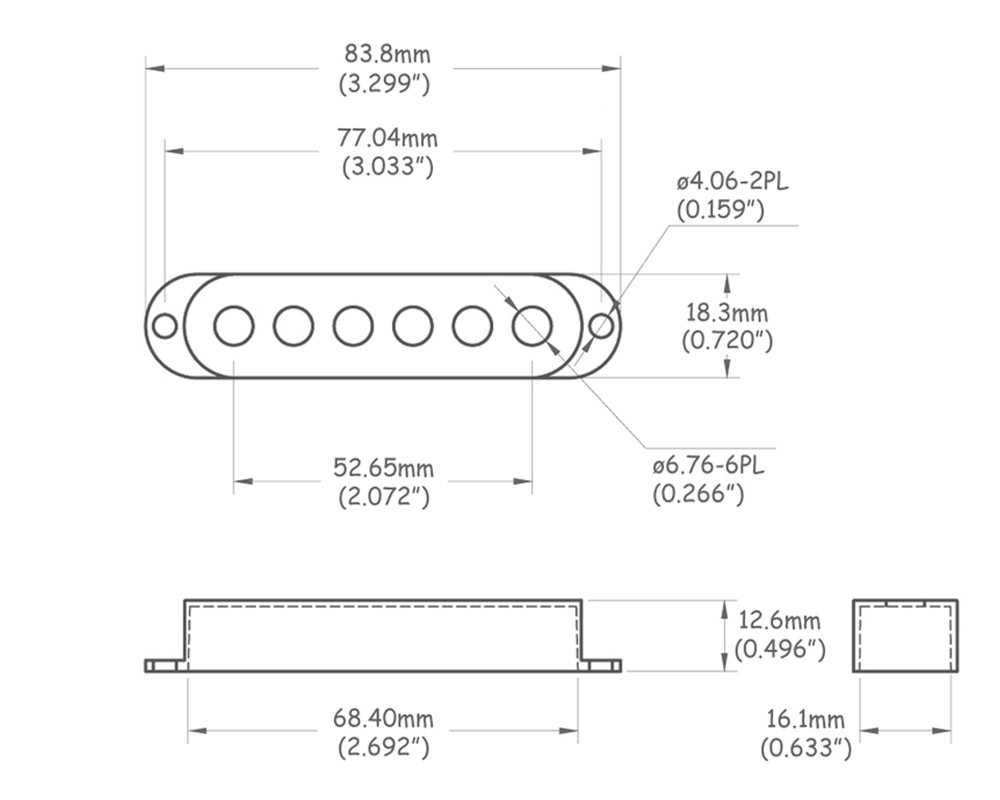

1/4" Kit Spec

|

|

|

|

|

|

|